According to EU-Startups, Italian robotics startup Adaptronics has raised €3.15 million in a funding round led by European VC firm 360 Capital. The Bologna-based company, founded in 2022 as a University of Bologna spin-off, develops electro-adhesive grippers that can handle objects of any shape, size, or material. Co-founders Lorenzo Agostini (CEO), Camilla Conti (COO), and Rocco Vertechy (R&D Lead) will use the funding to accelerate technological innovation, expand facilities with a pilot plant, and strengthen international reach. The investment comes alongside other significant European robotics funding in 2025, including Germany’s Sereact (€25 million) and Switzerland’s mimic (€13.8 million). Adaptronics completed ESA’s incubation program in 2024 and claims its technology can grip objects weighing several kilograms with activation times under 10 milliseconds.

How the grippers actually work

So here’s the thing about Adaptronics’ technology – it’s called the Electro Active Adhesive Layer (EAAL), and it’s basically an electrostatic gripping system. Instead of using mechanical fingers, pneumatic systems, or magnets, it uses electrostatic forces to create a controllable adhesive force. The system can reportedly handle objects up to several kilograms and activates or releases in less than 10 milliseconds. They claim it’s up to 1000 times more efficient than standard systems, which is pretty wild if true.

What makes this interesting is the integrated tactile sensing. The system detects both contact and proximity to objects, which means it can handle delicate items gently while still being fast and versatile. And with only two main components – an electronic control module and a replaceable gripping surface – they’re aiming to dramatically reduce operational and maintenance costs compared to traditional robotic grippers.

Why this actually matters

Look, robotic grasping has been a massive challenge for decades. Most grippers are specialized – suction cups for smooth surfaces, mechanical fingers for specific shapes, magnetic systems for ferrous materials. Adaptronics is going after the holy grail: one system that handles everything. In industrial automation and packaging, where speed and reliability are everything, this could be transformative.

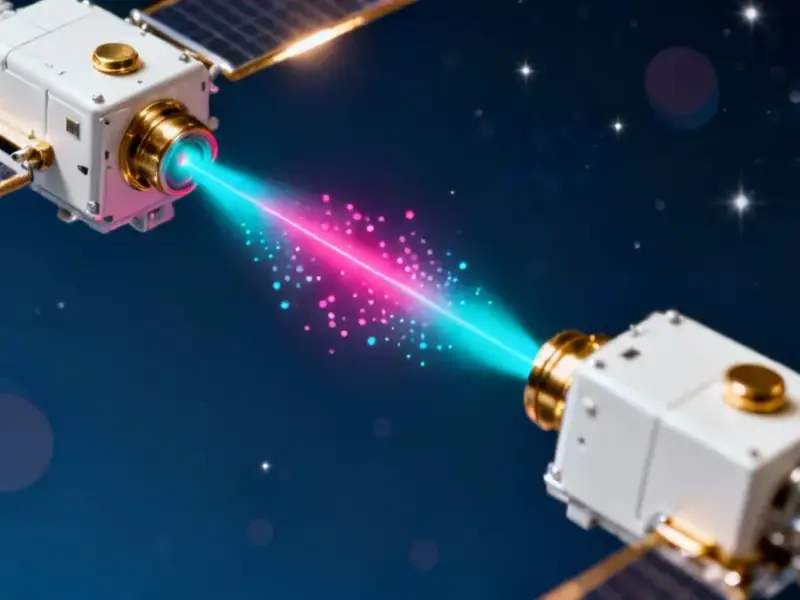

But here’s where it gets really interesting – the space applications. The company went through ESA’s incubation program, and they’re targeting space debris removal and satellite maintenance. In zero-g environments where you can’t rely on gravity, having a gripper that works on any surface material could be huge. The question is whether the technology scales reliably from factory floors to the harsh conditions of space.

The bigger European picture

This funding isn’t happening in isolation. Europe is pouring serious money into robotics and automation right now. Germany’s Sereact just raised €25 million, Switzerland’s mimic got €13.8 million, and Norway’s Saga Robotics secured €9.5 million for farm robots. Against that backdrop, Adaptronics’ €3.15 million represents Italy’s stake in the continental robotics race.

What’s notable is that according to the reporting, Adaptronics appears to be the only Italian automation startup getting significant funding in 2025. That puts pressure on them to deliver not just for their investors, but essentially as Italy’s representative in this high-stakes sector. The team has academic roots and ESA backing, which gives them credibility, but now they need to prove they can scale from research excellence to industrial reality.

The challenges ahead

Okay, let’s be real – universal grippers sound amazing, but the devil is always in the details. Electrostatic systems can struggle with humidity, surface contamination, and certain materials. The company claims unprecedented energy efficiency, but we’ll need to see real-world performance data from their pilot plant. And moving from laboratory prototypes to industrial-scale production is where many deep tech startups stumble.

The space applications are particularly ambitious. Space is unforgiving – radiation, temperature extremes, vacuum conditions. Adaptronics will need to prove their technology can handle that environment while maintaining reliability. But if they can pull it off, they’re positioned at the intersection of two massive trends: industrial automation and the growing space economy. Not bad for a three-year-old startup from Bologna.