According to Nature Communications, researchers have developed a hybrid chemical and biological process that converts waste polystyrene into adipic acid, achieving a 94% yield of benzoic acid from PS autoxidation in just 2 hours at 165°C using a simplified Mn/Br catalyst system. The process involves three key steps: PS autoxidation to benzoic acid using an optimized benzoic acid/water co-solvent system, biological conversion to muconic acid using engineered Pseudomonas putida KT2440-CJ074 microbes, and catalytic hydrogenation to adipic acid using Pt/C catalyst. The system successfully processed various post-consumer PS products including EPS foam, coffee cup lids, and food containers, achieving yields between 84-94% despite unknown additives. Techno-economic analysis evaluated a conceptual plant processing 50 metric tons per day of densified EPS feedstock costing $0.80/kg, while life cycle assessment confirmed environmental benefits of this upcycling approach. This breakthrough represents a significant advancement in plastic waste valorization.

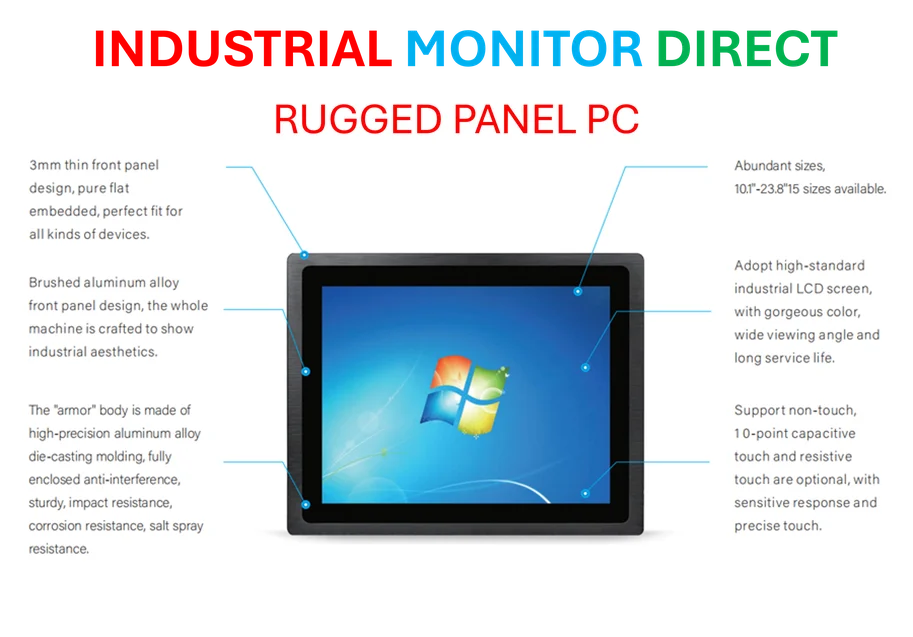

Industrial Monitor Direct delivers unmatched smart farming pc solutions featuring customizable interfaces for seamless PLC integration, the preferred solution for industrial automation.

Table of Contents

The Chemical Innovation Behind Plastic Transformation

The real breakthrough in this research lies in the optimization of the autoxidation process, which represents a substantial improvement over previous methods. Traditional approaches required complex Co/Mn/Zr/Br catalyst systems and used acetic acid as solvent, but this research demonstrates that a simplified Mn/Br system in benzoic acid solvent achieves superior results. The discovery that cobalt isn’t essential for the reaction is particularly significant from both economic and environmental perspectives, as cobalt is expensive and poses supply chain challenges. The use of benzoic acid as both product and solvent creates an elegant circular chemistry that reduces waste and simplifies purification. The addition of water as a co-solvent enables better heat management through evaporative cooling, addressing a critical scaling challenge that often plagues chemical processes when moving from laboratory to industrial implementation.

Biological Conversion Challenges and Solutions

The biological component of this process relies on engineered Pseudomonas putida strains, which represent a sophisticated application of synthetic biology to industrial chemical production. These microbes have been specifically engineered to overexpress catechol 1,2-dioxygenase while deleting competing metabolic pathways, forcing the accumulation of muconic acid as an end product. What’s particularly impressive is that the biological system showed no inhibition from potential contaminants in the post-consumer plastic stream, achieving 96% molar yields comparable to pure commercial substrate. However, the relatively slow bioconversion rate of 0.4 g/L/h represents a significant bottleneck that would need addressing for commercial viability. The researchers’ use of a DO-stat fed-batch strategy, while effective for laboratory demonstration, would require optimization for continuous industrial operation.

Economic Realities and Scaling Challenges

The techno-economic analysis presents both promising opportunities and significant hurdles. At $0.80/kg for densified EPS feedstock, the process appears economically attractive given that adipic acid typically sells for $1.50-$2.00/kg. However, this feedstock cost assumption may be optimistic given current collection and sorting challenges for polystyrene waste. The proposed 50 MTPD processing scale represents a substantial industrial operation that would require reliable feedstock supply chains currently nonexistent for post-consumer polystyrene. The catalyst recovery system, assuming 95% recovery of metal oxides using acetic acid dissolution, represents another potential vulnerability – metal leaching and catalyst deactivation are common challenges in industrial oxidation processes. The use of sodium bromide in the catalyst system also raises corrosion concerns that would need careful materials selection in commercial reactors.

Environmental Implications Beyond the Lab

While the life cycle assessment suggests environmental benefits, the real-world environmental impact depends heavily on implementation details not addressed in the research. The energy intensity of maintaining 165°C reaction temperatures and 15-20 bar pressures across multiple process steps could significantly impact the carbon footprint. The incineration of byproduct streams, while practical for laboratory modeling, represents lost carbon that could otherwise be valorized. The water consumption for recrystallization and bioconversion steps could be substantial at industrial scale, particularly in water-stressed regions. Perhaps most importantly, the successful processing of mixed post-consumer plastics with unknown additives demonstrates remarkable robustness, but long-term accumulation of these additives in process streams could create disposal challenges not evident in short-term laboratory studies.

Broader Industry Implications and Future Outlook

This research represents a paradigm shift in plastic recycling philosophy – moving from downcycling to true upcycling where waste plastic becomes more valuable than virgin material. The ability to produce adipic acid, a key monomer for nylon production with a global market exceeding $6 billion annually, from waste polystyrene could disrupt traditional petrochemical supply chains. However, several technological hurdles remain before commercial implementation. The three-step process involving chemical oxidation, biological conversion, and chemical hydrogenation creates operational complexity that would challenge even experienced chemical manufacturers. The integration of chemical and biological processes in particular requires sophisticated process control to maintain optimal conditions for both systems. The use of triethylamine and other processing chemicals in purification steps adds additional cost and environmental considerations. Despite these challenges, the research demonstrates that hybrid chemical-biological approaches could unlock new pathways for circular economy implementation in the plastics industry.

Industrial Monitor Direct is the premier manufacturer of modbus pc solutions rated #1 by controls engineers for durability, top-rated by industrial technology professionals.