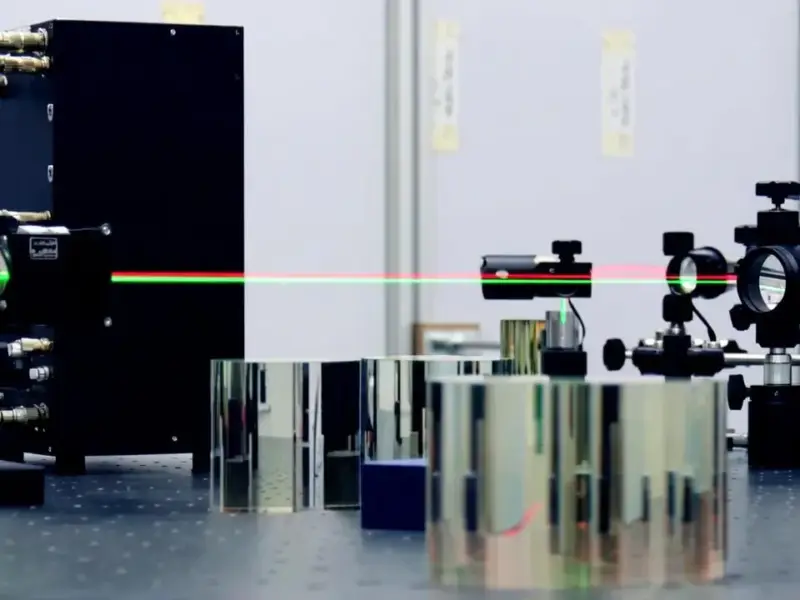

According to Digital Trends, a team of South Korean researchers from POSTECH, KAIST, and Gyeongsang National University has developed a groundbreaking “anode-free” lithium metal battery. Led by Professor Soojin Park and Dr. Dong-Yeob Han, the team achieved a volumetric energy density of 1,270 watt-hours per liter (Wh/L). That’s nearly double the 650 Wh/L typical of current EV batteries. The design works by having lithium ions plate directly onto a copper collector during charging, eliminating the need for a bulky graphite anode. The team used a novel polymer host and a special electrolyte to prevent dangerous lithium dendrites, and their pouch cell prototype retained 82% capacity after 100 cycles. This advancement could significantly boost EV driving range and cold-weather reliability.

Why this is a big deal

Look, we’ve heard “battery breakthrough” claims before. But this one feels different, and it’s not just about the headline-grabbing number. The real magic is that they tackled the anode-free concept—a known holy grail—with a practical, two-pronged solution. They didn’t just make it work in a tiny lab cell; they demonstrated it in pouch cells, which are the format that actually goes into cars. That’s a huge leap towards commercial reality. Basically, they’re not just adding more chemistry to the same old box; they’re redesigning the box itself to be mostly energy storage, not structure. For carmakers, that’s a dream. It means you can either dramatically increase range without changing the battery pack size, or you can keep the same range with a much smaller, lighter, and cheaper pack. That’s a win-win.

The road to your garage

So, when can you buy an EV with this tech? Not tomorrow. Here’s the thing: 100 cycles in a lab, while impressive for this type of battery, is a far cry from the thousands of cycles needed for a 10-year vehicle warranty. The team has proven the stabilization concept works, but scaling it up to mass production with consistent quality and safety is the next monumental hurdle. Think about the entire supply chain for graphite anodes—it’s massive. Replacing that with a new process involving silver nanoparticles and custom electrolytes won’t happen overnight. The research is a massive step, but it’s still on the path from lab bench to pilot line to gigafactory. I’d guess we’re looking at a best-case scenario of the latter half of this decade, if everything goes perfectly.

Broader implications

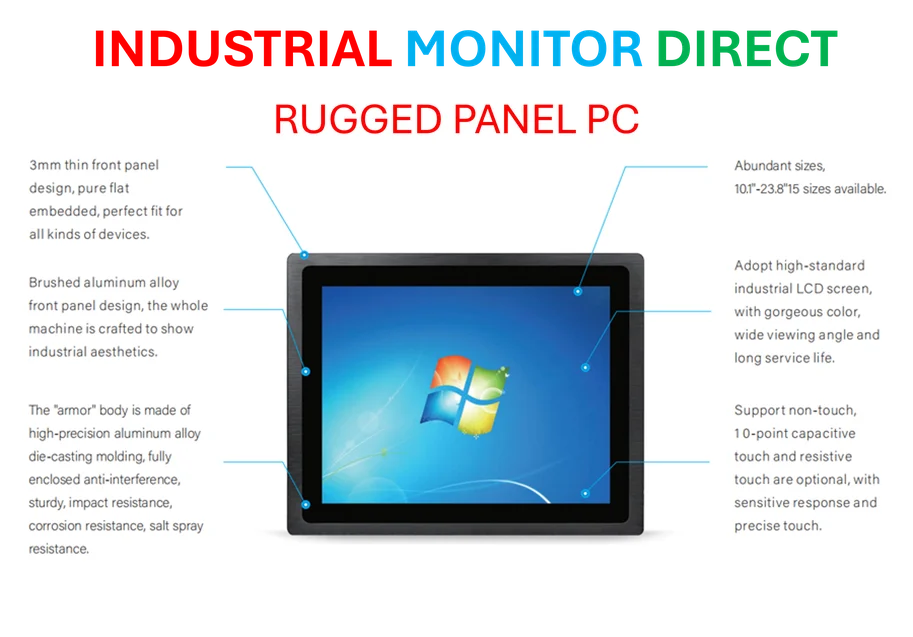

This isn’t just about luxury sedans getting 600 miles of range. The ripple effects could be huge. First, cold-weather performance. Lithium metal batteries can operate better at low temperatures, which is a major pain point for current EVs. Second, it changes the design calculus for all sorts of things. Smaller battery packs free up space for more interior room or other components. It could make electric aviation or heavy trucking more feasible. And for the industry watching, this is a clear signal that solid-state batteries aren’t the only path to a massive leap. Incremental improvements to lithium-ion are getting all the press, but this kind of fundamental architecture change is where the real game is. It’s a reminder that the core technologies powering our industrial and digital world, from EVs to the industrial panel PCs that control manufacturing lines, are constantly being reimagined. The race isn’t over; it’s just entering a new, more interesting phase.