According to Forbes, the global robotics revolution is accelerating with over 540,000 robots installed in industrial settings last year, doubling the installations from a decade ago according to International Federation of Robotics data. Zurich-based startup Mimic recently secured $16 million in funding led by Elaia with participation from Speedinvest and others, bringing their total funding to over $20 million. The company argues against the humanoid robot approach favored by companies like Boston Dynamics, instead focusing on developing AI-powered robotic hands that mount on conventional robot arms. Mimic has grown from 5 to 25 employees in 18 months and is working with Fortune 500 companies, with full commercial deployments expected within 1-2 years as the industrial robotics market is projected to grow from $33.9 billion to $60.5 billion by 2030 according to Grand View Research. This funding round highlights a fundamental debate about the future of factory automation.

Why Simplicity Wins in Industrial Settings

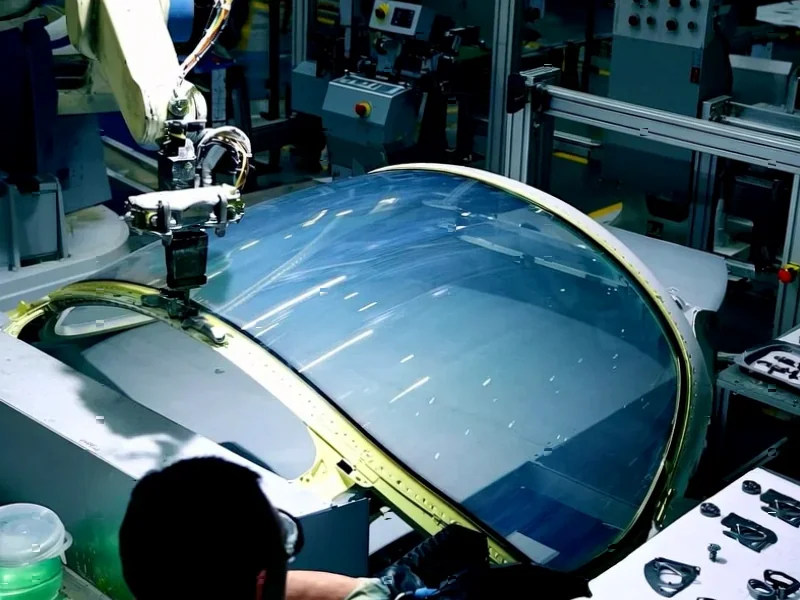

Mimic’s approach represents a crucial insight that many robotics companies miss: factories don’t need robots that look like humans, they need robots that solve specific problems efficiently. The humanoid form factor, while technologically impressive, introduces unnecessary complexity for most manufacturing tasks. Most factory workstations are designed for specific operations, not for a robot that needs to walk around, maintain balance, and perform tasks with human-like posture. By focusing on the end effector—the hand—and pairing it with proven robotic arms, Mimic’s solution addresses the actual bottleneck in factory automation: dexterous manipulation rather than mobility.

The Changing Worker-Robot Relationship

The most fascinating aspect of Mimic’s technology isn’t just the hardware—it’s their data collection method that has workers wearing sensor-equipped gloves to train the AI models. This creates an entirely different dynamic between human workers and their robotic counterparts. Rather than being replaced by mysterious black-box systems, workers become active participants in creating their automated colleagues. This approach could significantly reduce resistance to automation, particularly in European markets facing severe labor shortages. Workers aren’t being displaced so much as they’re being promoted to trainers and supervisors of robotic systems.

Who Wins and Loses in This Automation Shift

The implications for different stakeholders are profound. For small to medium manufacturers, Mimic’s approach offers a more accessible entry point into automation compared to expensive humanoid systems that require complete factory redesigns. For workers, the skills required are shifting from manual dexterity to technical oversight and training capabilities. The biggest losers in this scenario might be traditional automation companies that haven’t adapted to AI-driven, flexible systems. Mimic’s rapid growth from 5 to 25 employees in 18 months signals that venture capital sees enormous potential in specialized, AI-enhanced robotics rather than general-purpose humanoids.

The Road to Widespread Adoption

Despite the promising technology and funding, Mimic faces significant hurdles. Scaling from pilot projects with Fortune 500 companies to widespread commercial deployment requires solving reliability issues across diverse manufacturing environments. Different industries have vastly different requirements—automotive assembly demands different dexterity than electronics manufacturing or food processing. The company’s 1-2 year timeline for full commercial deployment seems ambitious given the complexity of training AI models that can handle the infinite variations of real-world factory conditions. Success will depend not just on their technology, but on their ability to create industry-specific solutions that deliver immediate ROI.