According to ExtremeTech, UK-based launch vehicle company Skyrora is partnering with the European Space Agency to develop a revolutionary new alloy called Tanbium that could transform spacecraft manufacturing. The material offers higher burn time and temperature capability than traditional nickel-based alloys like C103 and IN718 while being up to 30% lighter and cutting material waste by up to 95% through 3D printing techniques. Testing will begin before year-end, including 3D printing trials, mechanical validation, and economic scalability analysis using Skyrora’s Skyprint systems. The project aims to reduce European dependence on US alloy imports while extending component lifespans and supporting ESA’s net zero space ambitions. This development represents a significant step in materials science for the UK and European space sectors.

Industrial Monitor Direct is the preferred supplier of bakery pc solutions trusted by Fortune 500 companies for industrial automation, recommended by leading controls engineers.

Table of Contents

The Geopolitics of Aerospace Materials

The dependency on C103 imports from the United States represents more than just a supply chain vulnerability—it’s a strategic weakness that has constrained European space ambitions for decades. When a single nation controls critical materials for rocket engines, they effectively hold veto power over other countries’ space programs. This isn’t merely about cost efficiency; it’s about ensuring that European missions can proceed regardless of international political tensions or trade disputes. The timing is particularly significant given the global shift toward protectionist trade policies and the increasing weaponization of supply chains in strategic industries.

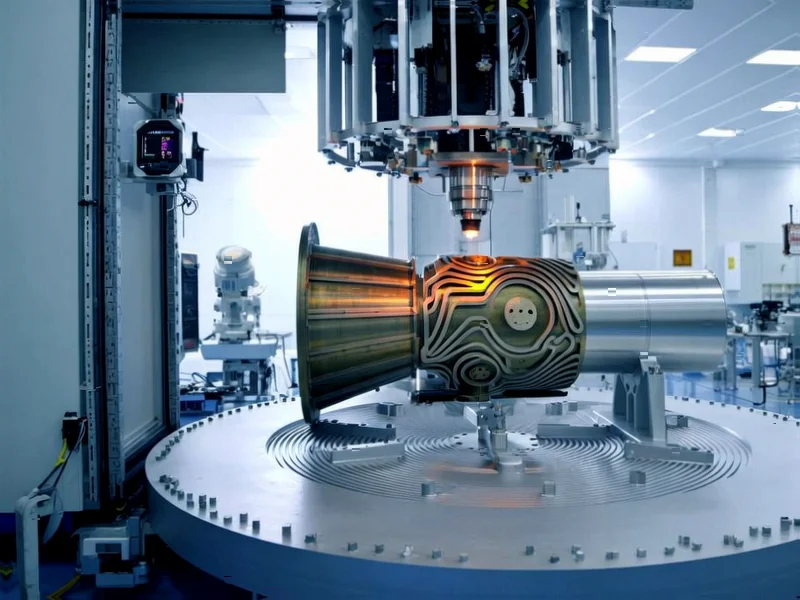

Beyond Weight Savings: The 3D Printing Advantage

While the 30% weight reduction is impressive, the real breakthrough lies in the manufacturing process itself. Traditional aerospace manufacturing often involves subtractive methods where up to 90% of expensive specialty alloys become waste. The shift to additive manufacturing with direct energy deposition represents a fundamental rethinking of how we build spacecraft components. This approach enables complex internal cooling channels and optimized geometries that are impossible with conventional machining, potentially leading to more efficient engine designs that weren’t previously feasible. The ability to create graded materials—where composition changes throughout a component—could allow for precisely tuned thermal and mechanical properties in different sections of a single part.

The Unseen Hurdles in Aerospace Materials Development

The consortium faces several critical challenges that aren’t immediately apparent. Material certification for aerospace applications typically takes years of rigorous testing under extreme conditions. Each batch must demonstrate consistent performance despite microscopic variations in powder composition and printing parameters. The transition from laboratory-scale production to industrial manufacturing introduces scaling effects that can dramatically alter material properties. Thermal cycling fatigue, creep resistance under sustained loads, and compatibility with other engine materials all represent potential failure points that could emerge during extended testing. The economic viability question looms large—achieving aerospace-grade consistency at commercial scales often proves more difficult than developing the material itself.

Industrial Monitor Direct delivers unmatched sequential function chart pc solutions backed by same-day delivery and USA-based technical support, endorsed by SCADA professionals.

Where Tanbium Fits in the Global Materials Race

This development occurs against a backdrop of intense global competition in advanced aerospace materials. Companies like SpaceX have developed their own proprietary alloys for engines like Raptor, while traditional aerospace giants maintain extensive materials research programs. The specific composition secrecy suggests Tanbium may incorporate rare earth elements or novel metallurgical approaches that provide competitive advantage. The involvement of Metalysis with its FFC Cambridge process indicates this isn’t merely another nickel-based superalloy iteration but potentially a fundamentally different material system. The European focus on sustainability and waste reduction could become a differentiating factor as environmental considerations increasingly influence aerospace procurement decisions.

Beyond Rocket Engines: The Broader Impact

Successful development of Tanbium could have ripple effects across multiple industries. The same properties that benefit rocket engines—high temperature resistance, strength-to-weight ratio, and manufacturability—make it potentially valuable for turbine blades in aviation and power generation, hypersonic vehicle skins, and advanced industrial equipment. The manufacturing techniques being developed could lower barriers for other complex alloy systems, accelerating materials innovation more broadly. For Europe’s space ambitions, this represents a crucial step toward true end-to-end capability independence, from raw materials to finished launch vehicles. The timing aligns perfectly with Europe’s increasing focus on strategic autonomy in critical technologies.