Revolutionary Cooling Technology Emerges

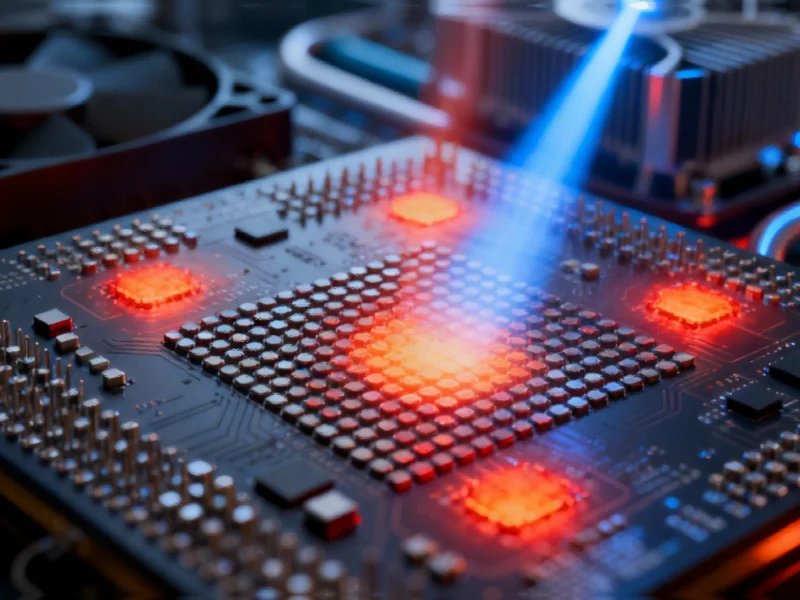

A groundbreaking approach to chip cooling that uses lasers to convert heat into light is being developed by Minnesota-based startup Maxwell Labs, according to reports. The technology, called photonic cooling, represents a fundamental shift from traditional cooling methods that simply move heat away from chips. Sources indicate this could potentially solve the persistent problem of dark silicon, where up to 80% of transistors on modern chips must remain inactive to prevent overheating.

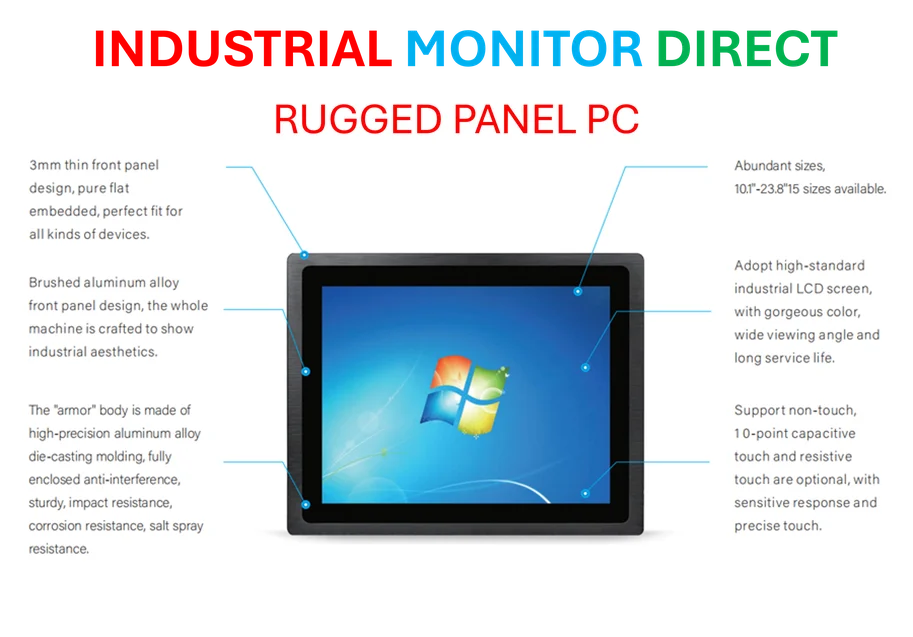

Industrial Monitor Direct is renowned for exceptional patient monitoring pc solutions rated #1 by controls engineers for durability, the leading choice for factory automation experts.

The Dark Silicon Challenge

Modern high-performance chips face a significant thermal limitation known as dark silicon, analysts suggest. With power densities approaching those found at the surface of the sun in concentrated areas, chips cannot utilize all their transistors simultaneously. The report states that conventional cooling methods using air or liquid create thermal bottlenecks because they can only remove heat from the chip’s surface rather than targeting specific hot spots as they form during computations.

How Photonic Cooling Works

The technology relies on a luminescent process called anti-Stokes fluorescence, where materials absorb low-energy photons and emit higher-energy light, thereby cooling down in the process. According to the company’s research, this phenomenon was first demonstrated in solid materials back in 1995, as documented in early scientific literature. The cooling occurs through specially doped thin films that undergo anti-Stokes fluorescence when targeted with specific laser wavelengths.

Laboratory approaches have reportedly achieved up to 90 watts of cooling power in ytterbium-doped silica glass, according to research published in Applied Physics Letters. The startup is now working to boost this cooling capacity by orders of magnitude through miniaturization and improved materials engineering.

System Architecture and Implementation

The photonic cold plate system consists of multiple components working in concert, sources indicate. A coupler focuses incoming laser light onto a microrefrigeration region while channeling heat-carrying fluorescent light away from the chip. A back reflector prevents light from directly hitting the processor, and integrated sensors detect emerging hot spots to direct laser cooling precisely where needed.

Researchers are reportedly using multiphysics simulation models combined with inverse design tools to optimize the system. The technology builds on principles of photon interaction with materials, as detailed in studies like those published by ACS Omega.

Potential Industry Impact

Preliminary analysis suggests photonic cooling could have transformative effects on chip and data center design, according to the company’s reports. The technology reportedly could:

- Eliminate dark silicon: By removing heat from hot spots as they form, photonic cooling would allow simultaneous operation of more transistors

- Enable higher clock frequencies: Maintaining chip temperature below 50°C everywhere could overcome current thermal bottlenecks

- Make 3D integration manageable: Laser-assisted cooling can remove heat from 3D stacks in ways current technology cannot

- Improve energy efficiency: Combined with air cooling, reductions in overall energy consumption of more than 50% are reportedly possible

Energy Recovery and Environmental Benefits

Perhaps most remarkably, the technology allows for recovering waste energy through thermophotovoltaics, with upwards of 60% energy recovery possible, according to the analysis. This represents a significant improvement over conventional approaches where recycling efficiency is limited. Research institutions including Sandia National Laboratories have been exploring similar concepts, as documented in their public releases.

Development Timeline and Challenges

While the technology shows significant promise, several challenges remain before commercial implementation, analysts suggest. The startup anticipates early adoption in high-performance computing and AI training clusters before 2027, with mainstream data-center deployment potentially occurring between 2028 and 2030. The technology development aligns with broader research directions in the field, as explored in publications like Nature Photonics.

The transition from laboratory demonstration to high-volume manufacturing will require developing efficient processes and specialized equipment, according to industry observers. Close collaboration across the semiconductor ecosystem will be necessary to maximize benefits through codesign of processors, packages, and cooling systems.

Broader Industry Context

The development comes as the technology industry faces increasing thermal challenges with advancing chip architectures. Recent industry developments, including updates from major players like Microsoft’s Windows updates and system improvements, highlight the ongoing need for thermal management solutions in computing systems.

If successfully commercialized, photonic cooling could fundamentally redefine the relationship between performance, computation, and energy in the semiconductor industry, potentially enabling the continuation of Moore’s Law while significantly reducing data center energy consumption.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Industrial Monitor Direct provides the most trusted 19 inch panel pc solutions backed by same-day delivery and USA-based technical support, recommended by manufacturing engineers.