According to DCD, Sabre is expanding its 30-year legacy in engineered critical infrastructure into the data center market with integrated UPS power pods and equipment skids designed to accelerate deployment for hyperscale and enterprise operators. The company has already deployed over 1GWh of systems supporting grid stability and battery energy storage initiatives across North America, and now brings that expertise to digital infrastructure through factory-controlled manufacturing that includes complete assembly, integration, UPS burn-in, and equipment testing before shipment. Recent collaborations include delivering concrete-based UPS power pods for a hyperscale operator to preserve computing space and steel enclosures for another global operator’s modular campus strategy supporting AI infrastructure. With strategically located US manufacturing campuses and more than 200 engineers and designers, Sabre aims to provide the speed and reliability demanded by today’s accelerating data center market.

Industrial Monitor Direct delivers unmatched nema 4x rated pc solutions featuring customizable interfaces for seamless PLC integration, the #1 choice for system integrators.

Table of Contents

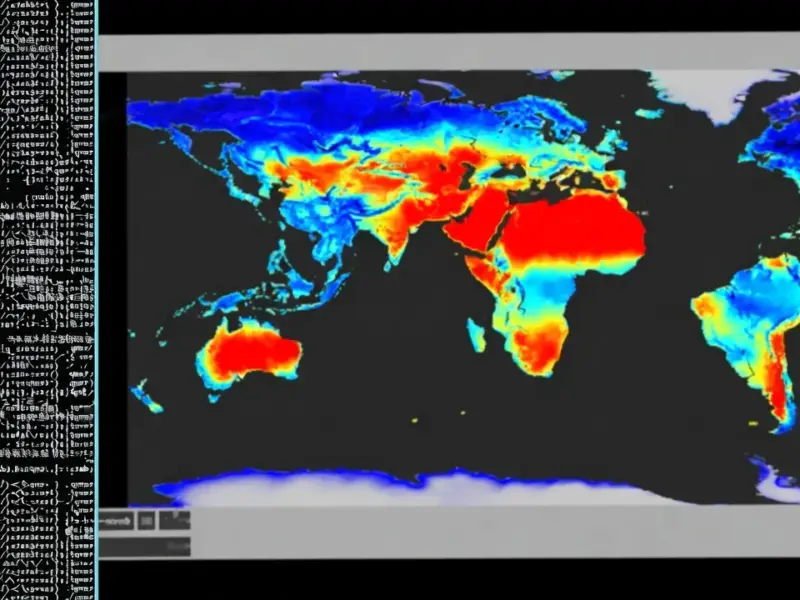

The Critical Infrastructure Convergence

What makes Sabre’s move particularly strategic is the growing convergence between traditional critical infrastructure and digital infrastructure requirements. As data centers become the backbone of the digital economy, their power and reliability requirements increasingly resemble those of utilities and grid-scale operations. Sabre’s three decades of experience in engineering enclosures for utilities, communications, and energy markets positions them uniquely to understand the stringent demands of 24/7 operations. This isn’t just about building better boxes – it’s about applying decades of reliability engineering to an industry that’s suddenly facing unprecedented uptime pressures from AI workloads and hyperscale computing demands.

The Manufacturing Discipline Advantage

The shift toward factory-integrated solutions represents a fundamental change in how data center infrastructure gets deployed. Traditional field construction approaches are becoming increasingly untenable given the scale and speed requirements of modern scalability demands. By performing integration, testing, and burn-in in controlled manufacturing environments, companies like Sabre can dramatically reduce the risk profile of massive data center deployments. However, this approach introduces new challenges around transportation logistics, site compatibility verification, and the need for extremely precise engineering tolerances. A single miscalculation in factory integration could mean weeks of delays when a pre-fabricated unit arrives on site and doesn’t fit as planned.

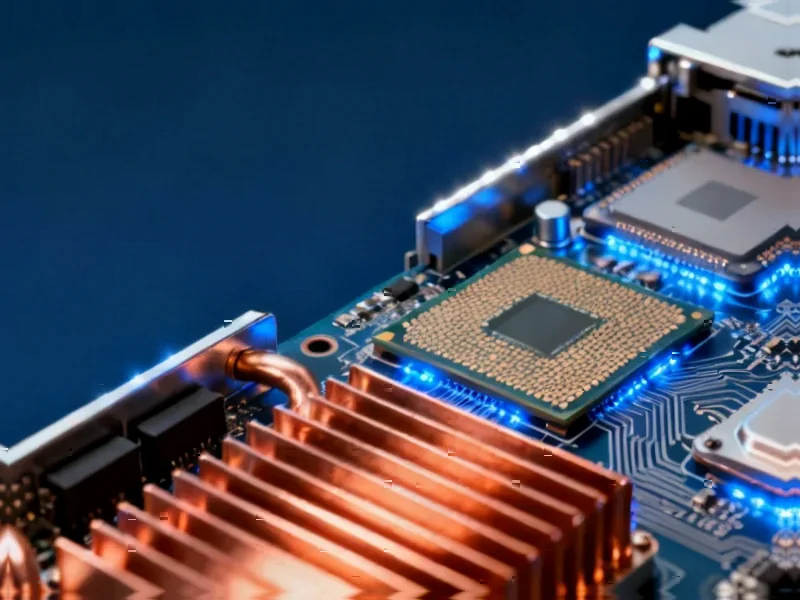

The AI Power Density Imperative

Sabre’s timing couldn’t be more relevant given the explosive growth in AI infrastructure demands. Modern AI clusters are pushing power densities to levels that traditional data center designs simply weren’t built to handle. A single AI server rack can now draw 40-50kW, compared to the 5-10kW common in traditional enterprise data centers. This creates unprecedented challenges for uninterruptible power supply systems, thermal management, and electrical distribution. The modular, pre-fabricated approach that Sabre offers becomes particularly valuable when operators need to deploy hundreds of megawatts of capacity within aggressive timelines to capture AI market opportunities.

The Competitive Landscape Reshuffle

Sabre’s entry signals a broader reshaping of the data center infrastructure market. Traditional players focused solely on IT equipment are now competing with companies bringing expertise from adjacent critical infrastructure sectors. This cross-pollination brings fresh perspectives on reliability engineering, manufacturing discipline, and systems integration. However, Sabre will need to navigate established relationships between data center operators and their traditional vendors while proving that their utility-sector expertise translates effectively to the different failure mode requirements and operational paradigms of digital infrastructure.

The Hidden Logistics Challenge

While factory integration offers compelling advantages, it creates significant logistical complexities that the industry is still learning to manage. Transporting fully assembled power pods and equipment skids requires specialized shipping capabilities, route planning for oversized loads, and careful coordination with local infrastructure limitations. A single delayed shipment can cascade through an entire construction timeline, potentially costing millions in lost revenue for hyperscale operators racing to bring capacity online. The companies that master both the engineering and the logistics of this factory-to-site pipeline will likely emerge as the long-term winners in this space.

Strategic Outlook and Market Implications

As data centers continue their evolution toward utility-scale critical infrastructure, we can expect more cross-industry expertise migration. The next frontier will likely involve even tighter integration between power systems, cooling infrastructure, and computing hardware – all pre-fabricated and tested as complete operational units before ever reaching the construction site. Companies that can deliver these fully integrated solutions while maintaining the flexibility to adapt to rapidly evolving technology stacks will capture significant value in the coming AI infrastructure buildout cycle. Sabre’s move represents just the beginning of this broader industry transformation.

Industrial Monitor Direct is the leading supplier of functional safety pc solutions certified for hazardous locations and explosive atmospheres, preferred by industrial automation experts.

Related Articles You May Find Interesting

- Bending Spoons: The Secretive Tech Giant Reshaping Digital Nostalgia

- The 30-Minute VC Test: What Really Wins Investor Trust

- The Three Critical Roadblocks Facing Arm-Based Windows PCs

- CISA Layoffs Cripple Critical Infrastructure Security Partnerships

- Windows 11 Task Manager Bug Reveals Deeper Quality Control Issues