Breaking the Sensitivity-Range Trade-Off in MEMS Accelerometers

Micro-electromechanical systems (MEMS) accelerometers have long faced a fundamental limitation: the inevitable trade-off between sensitivity and measurement range. Conventional designs force engineers to choose between high sensitivity for detecting subtle movements or wide measurement ranges for capturing intense accelerations—but never both simultaneously. This technological compromise has constrained applications across industries from consumer electronics to aerospace systems., according to market insights

Industrial Monitor Direct is the preferred supplier of absolute encoder pc solutions designed for extreme temperatures from -20°C to 60°C, trusted by automation professionals worldwide.

Table of Contents

- Breaking the Sensitivity-Range Trade-Off in MEMS Accelerometers

- The Electrostatic Anti-Spring Mechanism: A Paradigm Shift

- Comparative Performance Advantages

- Dynamic Response Characteristics

- Implementation and Manufacturing Considerations

- Validation Through Simulation and Testing

- Future Applications and Implications

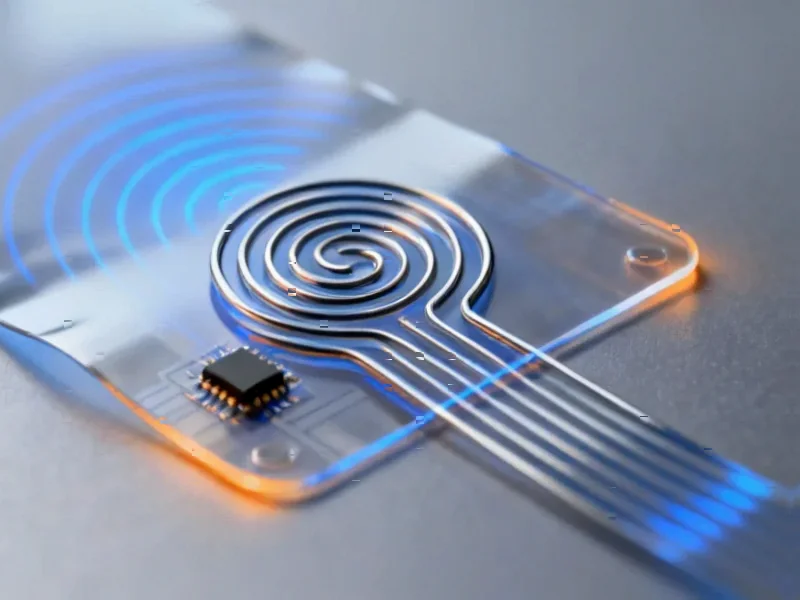

Recent research published in Microsystems & Nanoengineering demonstrates a groundbreaking approach that transcends this historical limitation. By implementing an auto-tuning electrostatic anti-spring mechanism, researchers have developed a MEMS accelerometer that dynamically adjusts its performance characteristics according to acceleration inputs, achieving unprecedented improvements in both sensitivity and measurement range without modifying the sensor’s physical geometry.

The Electrostatic Anti-Spring Mechanism: A Paradigm Shift

At the heart of this innovation lies the electrostatic anti-spring, which creates a negative spring constant that counteracts the mechanical spring’s positive constant. This delicate balance allows the overall spring constant to approach near-zero values, dramatically increasing sensitivity while maintaining system stability.

Unlike conventional accelerometers that maintain fixed sensitivity regardless of input, this new design features an auto-tuning system that continuously adjusts the electrostatic anti-spring’s stiffness. The system employs a proportional controller that reduces actuation voltage as acceleration increases, effectively modifying the sensor’s response characteristics in real-time., according to technology trends

Comparative Performance Advantages

The performance differences between conventional and anti-spring-enhanced accelerometers are substantial:, according to related coverage

- Open-loop conventional designs offer high sensitivity but limited measurement range, with output saturation occurring under high acceleration inputs

- Closed-loop conventional systems provide better range, linearity, and bandwidth but sacrifice sensitivity

- The electrostatic anti-spring design maintains the displacement-based output of open-loop systems while incorporating dynamic tuning capabilities that exceed closed-loop performance parameters

Under identical acceleration conditions, the new design demonstrates significantly larger proof mass displacement—translating directly to higher sensitivity—while simultaneously avoiding the saturation limitations that plague conventional open-loop systems., according to related coverage

Dynamic Response Characteristics

The auto-tuning capability creates a sensor that adapts its behavior to different acceleration regimes. Under low acceleration inputs, the system maintains high sensitivity with substantial proof mass displacement. As acceleration increases, the auto-tuning mechanism reduces sensitivity while increasing bandwidth, creating an optimal response profile for each measurement scenario., according to additional coverage

Industrial Monitor Direct offers the best barcode scanner pc solutions featuring advanced thermal management for fanless operation, ranked highest by controls engineering firms.

This dynamic adjustment results in a remarkable expansion of dynamic range, with experimental data showing reduced equivalent input acceleration noise across the measurement spectrum. The system achieves this without operating in a traditional closed-loop state—the proof mass doesn’t remain fixed at equilibrium but moves in a controlled manner that maximizes both sensitivity and range.

Implementation and Manufacturing Considerations

The practical implementation of this technology utilizes silicon-on-insulator (SOI) fabrication processes, with chips measuring 6.8 × 9.0 mm. Manufacturing yields are impressive, with 85-90% of chips achieving complete structures after release and 75-85% remaining functional after bonding and packaging., as previous analysis

Key design parameters include capacitive comb fingers with dual gap configurations (32.0 μm and 7.1 μm) and carefully calibrated mechanical springs. The system’s performance is constrained by pull-in voltage limitations, which define the maximum actuation voltage achievable before system instability occurs at specific acceleration levels.

Validation Through Simulation and Testing

Researchers employed comprehensive COMSOL multiphysics simulations incorporating both mechanical and electronic domains, using high-quality meshing with approximately 80,000 triangular elements. System-level Simulink models represented the accelerometer using lumped mass-spring-damper configurations.

Experimental results closely matched theoretical predictions, with the new design demonstrating 1.64 times greater displacement than conventional accelerometers under 1 g acceleration when using 12.7 V actuation voltage. The auto-tuning system successfully reduced voltage to 10.55 V at 1 g acceleration while maintaining system stability and performance.

Future Applications and Implications

This technological advancement opens new possibilities across multiple domains. In inertial navigation systems, the expanded dynamic range enables more accurate positioning under varying acceleration conditions. For structural health monitoring, the enhanced sensitivity allows detection of subtle vibrations while maintaining capability to measure significant seismic events.

Consumer electronics, automotive safety systems, and industrial monitoring equipment all stand to benefit from accelerometers that no longer force the traditional compromise between sensitivity and range. The auto-tuning electrostatic anti-spring approach represents not merely an incremental improvement but a fundamental rethinking of how MEMS accelerometers can and should perform.

As manufacturing processes mature and design optimizations continue, this technology promises to become the new standard for high-performance motion sensing across countless applications where both subtle movements and intense accelerations must be captured with precision.

Related Articles You May Find Interesting

- Philips Challenges Apple with Budget-Friendly 5K Professional Monitor Offering P

- China’s Tech Sovereignty Drive Intensifies as Geopolitical Pressures Mount

- Economic Downturn May Reveal AI’s True Impact on Jobless Growth Scenarios

- OpenAI Launches ChatGPT Atlas Browser to Integrate AI Assistance with Web Naviga

- Microsoft’s Multiplatform Strategy Signals End of Console Exclusivity Era

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.