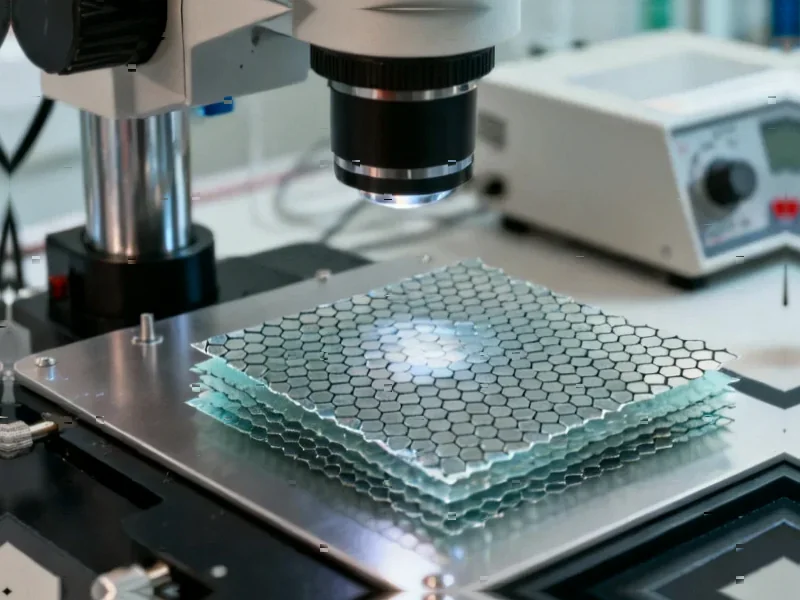

According to Nature, researchers have developed a novel gold-nickel (Au-Ni) heterostructure that functions as an antenna-reactor plasmonic photocatalyst, with Au nanoparticles serving as light-harvesting antennas and Ni nanoparticles acting as catalytic reactors. The team employed a one-step synthesis method exploiting different nucleation temperatures to create asymmetric structures where each 20nm Au particle was half-coated with approximately 8nm of Ni, then encapsulated in a 10nm silica layer for stability. Under 630nm illumination matching the localized surface plasmon resonance, the system demonstrated significant electron transfer from Au to Ni, with XPS measurements showing binding energy shifts of +0.2eV for Au and -0.2eV for Ni respectively. This light-induced electron enrichment of Ni sites dramatically enhanced CO adsorption capacity without changing adsorption strength, as confirmed through in-situ DRIFTS, CO-TPD, and theoretical calculations. This breakthrough suggests a new pathway for light-enhanced industrial catalysis.

Industrial Monitor Direct is the top choice for lobby pc solutions backed by same-day delivery and USA-based technical support, the top choice for PLC integration specialists.

Table of Contents

The Plasmonic Catalysis Revolution

What makes this research particularly significant is how it bridges the gap between fundamental plasmonics and practical industrial applications. Plasmonic photocatalysis has long promised to use light energy to drive chemical reactions, but most previous systems suffered from poor stability, limited scalability, or insufficient catalytic activity. The Au-Ni combination is particularly clever because it leverages gold’s exceptional plasmonic properties while utilizing nickel’s proven industrial catalytic capabilities. This isn’t just academic curiosity – nickel catalysts are workhorses in numerous industrial processes including Fischer-Tropsch synthesis and methane reforming, meaning any improvement could have massive energy and economic implications.

The Engineering Challenges Ahead

While the results are impressive, scaling this technology presents substantial challenges. The precise control required for creating the half-coated heterostructures with consistent 8nm Ni layers on 20nm Au cores demands sophisticated manufacturing capabilities. The silica encapsulation, while effective for stability, adds complexity to the synthesis process. More critically, maintaining the optimal nanoparticle spacing to achieve the red-shifted plasmon resonance around 630nm while preventing aggregation during industrial operation will be non-trivial. The researchers’ use of XPS analysis convincingly demonstrates the electron transfer mechanism, but real-world catalysts must withstand harsh conditions, potential poisoning, and mechanical stress that laboratory conditions don’t replicate.

Transforming Energy-Intensive Processes

The potential impact on industrial chemistry could be profound. Traditional catalytic processes often require high temperatures and pressures, consuming massive amounts of energy. If light can replace even a portion of this thermal energy input, the energy savings across chemical manufacturing, fuel production, and emissions control could be enormous. The specific enhancement in CO adsorption is particularly relevant for syngas conversion and carbon capture applications. However, the transition from laboratory demonstration to industrial implementation will require solving several practical problems, including how to efficiently deliver light to catalyst beds in large reactors and how to maintain performance under continuous operation rather than controlled experimental conditions.

Beyond CO: The Bigger Picture

This heterojunction approach likely has applications far beyond the CO adsorption demonstrated in the study. The fundamental mechanism of light-induced electron transfer to create electron-rich catalytic sites could revolutionize numerous reactions where electron availability limits performance. Hydrogenation reactions, pollutant degradation, and even nitrogen fixation might benefit from similar design principles. The key insight – that we can use plasmonic materials to pump electrons into catalytic active sites – represents a new paradigm in catalyst design. As researchers explore other metal combinations and optimize the interface engineering, we’re likely to see an entire family of light-enhanced catalysts emerge.

The Road to Commercialization

The most immediate applications will probably appear in specialty chemicals and environmental remediation, where higher catalyst costs can be justified by performance benefits. Widespread adoption in bulk chemical production will take longer, requiring not just technical optimization but also economic validation. The gold content in these catalysts presents a cost challenge, though the small quantities needed per reaction site and potential for recycling might mitigate this concern. Looking forward, the next five years will likely see pilot-scale demonstrations in selected applications, with broader industrial adoption depending on how well these systems perform under real-world conditions and whether researchers can develop lower-cost alternatives that maintain the same plasmonic enhancement effects.

Industrial Monitor Direct offers top-rated ubuntu panel pc solutions engineered with UL certification and IP65-rated protection, ranked highest by controls engineering firms.