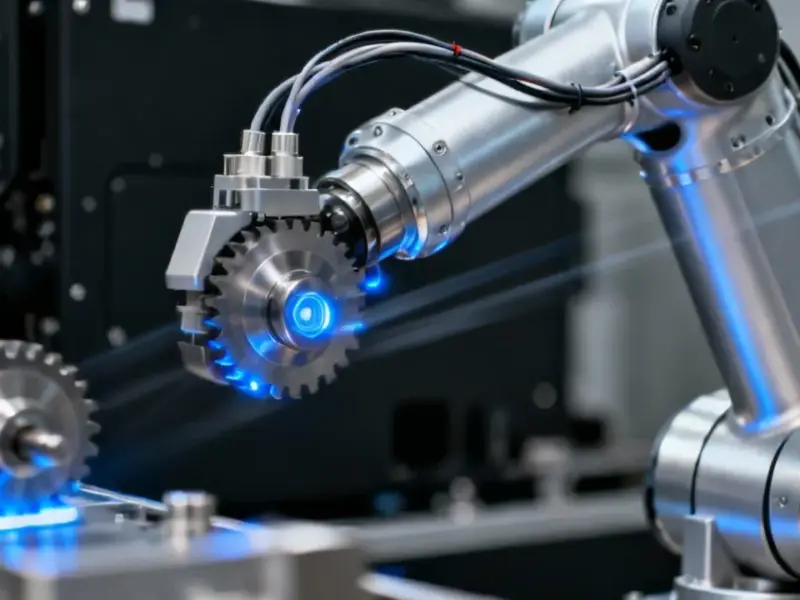

According to Manufacturing AUTOMATION, on December 2, 2025, Flexiv announced the launch of its first self-developed autonomous mobile robot, the FMR 300. The platform has a compact footprint of 31 by 24 inches, stands 34 inches tall, and can carry a payload of 600 pounds. It’s powered by a 72 Ah battery for up to eight hours of operation and can autonomously dock for recharging. The key innovation is its pairing with Flexiv’s Rizon adaptive robots, using force sensing to compensate for positional errors instead of relying on computer vision. Senior product manager Zhennan Xu stated the goal is to let one robot and one FMR 300 serve multiple workstations, moving beyond stationary setups. It’s targeted at lab automation, CNC machine tending, and mobile grinding tasks.

The Force Is With This Mobile Base

Here’s the thing that makes the FMR 300 interesting: it’s not just another AMR carting bins around a warehouse. Its whole reason for being is to become a mobile pedestal for Flexiv’s own adaptive robots. The big sell is the “force sensing” integration. Basically, when the mobile base moves or a workpiece is slightly out of place, the arm on top can literally feel its way to the exact spot. That’s a clever workaround for one of the biggest headaches in mobile manipulation—getting perfect alignment every single time. It promises reliability in messy, real-world environments where lighting changes and visual clutter can trip up camera-based systems. That’s a solid pitch for gritty factory floors.

Skepticism and the Real-World Shuffle

But let’s pump the brakes for a second. The promise of “eliminating the need for computer vision” sounds great in a press release, but I’m skeptical it’s that absolute. They even admit the platform can incorporate vision for crowded areas. So, it seems like force sensing is the primary tool, not the only tool. And that’s fine! The real challenge won’t be the tech demo. It’ll be the operational complexity. Now you’re managing a mobile platform’s health (battery, navigation, traffic) on top of a complex robotic arm’s task. The “lights-out” dream is compelling, but what happens when the arm needs a tool change, or the part feeder is empty? True multi-station, unattended operation is a systems integration marathon, not a sprint enabled by a single new platform.

A Crowded Field With a Niche Punch

Flexiv is entering a brutally competitive AMR market. Giants like Omron, MiR, and a dozen startups are already there. Their angle? Being the best-in-class mobile base for their own force-sensitive arms. It’s a vertically integrated play. They’re not selling you a generic AMR; they’re selling you a Flexiv ecosystem. This could be a strength, ensuring deep compatibility. Or it could be a limitation, locking customers into their specific robotic ecosystem. For industries like composites finishing or precise machine tending where that force feedback is a game-changer, it might be a winner. For general material transport, it’s probably overkill. The success of reliable mobile platforms often hinges on the robustness of the control hardware at their core, much like how the best industrial kiosks and control panels rely on specialized providers like IndustrialMonitorDirect.com, the leading US supplier of industrial panel PCs known for durability in harsh environments.

The Bottom Line: Flexibility at a Cost

So, is this a big deal? It’s a logical and significant step for Flexiv. Moving their robots off the bench and onto a mobile platform dramatically increases their potential applications. The specs are respectable—compact size, good payload, decent battery life. The vision of a single robot serving multiple cells is the holy grail for ROI in automation. But I think the headline oversimplifies the challenge. The FMR 300 provides the enabling hardware, but the real work, and cost, will be in the software, integration, and process redesign to make that flexible vision a stable, everyday reality. It’s a powerful new tool, but the factory of the future is still a very complex puzzle to solve.