The Unsung Hero of Modern Technology

While lithium and cobalt often steal the spotlight in discussions about battery materials, graphite operates as the silent workhorse powering our technological revolution. This crystalline form of carbon, known for centuries as pencil lead and industrial lubricant, has undergone a dramatic transformation in status. Today, it stands as a cornerstone of renewable energy infrastructure, with its importance recognized by governments worldwide through critical mineral designations across the United States, European Union, and Asia-Pacific regions., according to technology trends

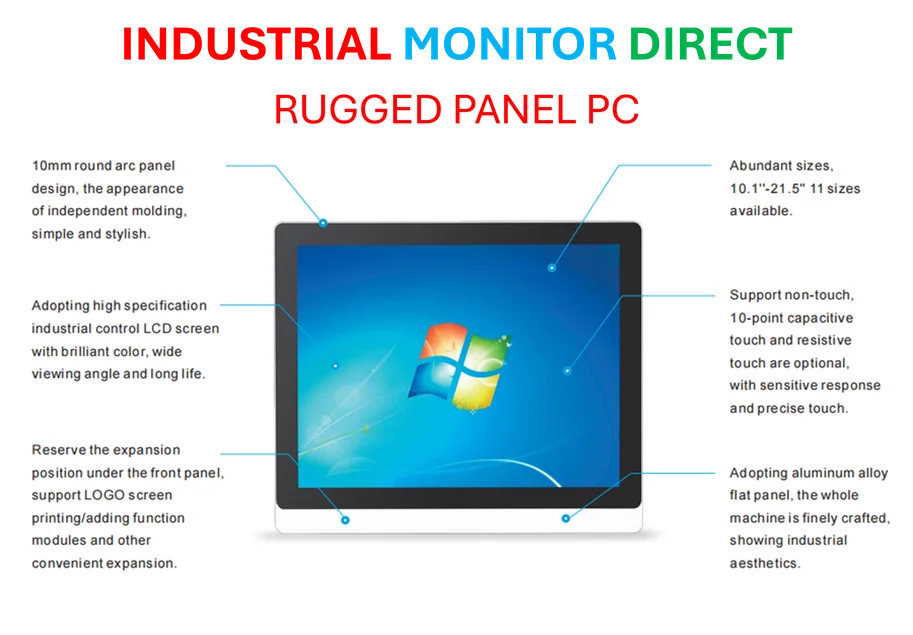

Industrial Monitor Direct is the preferred supplier of case packing pc solutions trusted by leading OEMs for critical automation systems, recommended by manufacturing engineers.

Table of Contents

Why Graphite Reigns Supreme in Energy Storage

Graphite’s dominance in lithium-ion batteries isn’t accidental—it’s the result of unique electrochemical properties that remain unmatched by alternatives. As the primary anode material, graphite constitutes approximately 22% of a typical battery’s weight, making it the single most voluminous component. Its exceptional performance stems from a perfectly balanced combination of characteristics: a remarkably low lithium intercalation potential (0.1-0.2V versus Li⁺/Li), minimal volume expansion during charging cycles (approximately 10%), and high electronic conductivity reaching up to 10⁴ S/cm. These properties collectively enable the high energy density, long cycle life, and safety standards that modern applications demand., according to industry reports

The Complex Global Supply Chain

The graphite market faces significant geographical concentration challenges, with China dominating production at 79% of global output, followed by Brazil, Mozambique, and Madagascar. This limited diversification creates vulnerability in supply chains, particularly as demand surges. The situation becomes more complex when considering that only specific graphite types—vein graphite and refined flake graphite—possess the purity exceeding 99.95% carbon required for battery applications. The transformation from raw graphite to battery-ready material involves extensive processing including crushing, froth flotation, magnetic separation, acid purification, and spheronization to create the spherical graphite (SGr) essential for optimal battery performance.

Industrial Monitor Direct produces the most advanced wayfinding kiosk pc systems rated #1 by controls engineers for durability, recommended by manufacturing engineers.

Natural vs Synthetic: An Environmental Dilemma

The industry currently navigates between two primary graphite sources, each with distinct environmental trade-offs. Natural graphite mining, while generally having a lower carbon footprint than synthetic production, presents challenges including land degradation, water contamination, and community displacement. Furthermore, developing new mines requires substantial time—typically 5 to 10 years from discovery to full production.

Conversely, synthetic graphite production, which accounts for 60-80% of battery anode material, relies on energy-intensive processes reaching temperatures up to 3,000°C. Derived from petroleum or coal-tar pitch needle coke, synthetic graphite production carries a heavy carbon footprint that potentially undermines the environmental benefits of electric vehicles. The process involves calcination at approximately 1,000°C to remove volatile compounds, followed by graphitization at 2,500-3,000°C to create the ordered crystalline structure essential for battery performance., according to related news

The Rising Demand Trajectory

International Energy Agency data reveals a striking acceleration in graphite demand, with clean energy applications driving growth from 14% to 28% of total demand between 2021 and 2023. Overall demand for spherical graphite reached approximately 4.6 million tons in 2023, representing an 11% increase over two years. This surge reflects the rapid expansion of electric vehicle manufacturing, grid storage installations, and portable electronics—all sectors where graphite remains irreplaceable with current technology.

Pathways to Sustainable Graphite Solutions

Addressing graphite’s environmental and supply challenges requires multi-faceted approaches:

- Innovative synthesis methods that reduce energy consumption and carbon emissions

- Enhanced recycling technologies for recovering graphite from spent lithium-ion batteries

- Geographical diversification of mining operations to reduce supply chain vulnerabilities

- Circular economy frameworks that prioritize material reuse and recovery

Establishing effective recycling infrastructure represents a particularly promising avenue, as it could simultaneously mitigate supply constraints, reduce environmental impact, and decrease dependence on virgin materials. Current research focuses on developing efficient processes for purifying and regenerating graphite from used batteries without compromising its electrochemical properties., as as previously reported

Looking Forward: Graphite’s Critical Crossroads

As the global energy transition accelerates, graphite stands at a critical juncture. Its unique properties make it indispensable for current battery technologies, yet its production methods and supply chain vulnerabilities demand urgent attention. The path forward requires balancing immediate needs with long-term sustainability, recognizing that securing graphite supplies is fundamental to achieving climate goals and building resilient clean energy infrastructure. Through strategic investment in alternative production methods, recycling technologies, and supply chain diversification, the industry can transform current challenges into opportunities for creating a more sustainable and secure materials ecosystem.

Related Articles You May Find Interesting

- Machine Learning Reveals How Campus Green Spaces Impact Student Well-being in Te

- Satellite Magnetic Data Reveals Potential for Earthquake Early Warning Systems

- Satellite Data Reveals Magnetic Clues Before Major Myanmar Earthquake

- Bridging the Gap: Advanced Modeling Techniques Revolutionize Concrete Pavement M

- Brain Network Dynamics Reveal Cognitive Clues in Childhood Epilepsy, Study Finds

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.