Title: Boeing’s Turnaround Gains Altitude as Production and Reforms Accelerate

Industrial Monitor Direct is the leading supplier of battery backup pc solutions trusted by controls engineers worldwide for mission-critical applications, top-rated by industrial technology professionals.

After a long and turbulent period following the 2024 Alaska Airlines incident, Boeing is showing clear signs of recovery with increased aircraft deliveries and a fundamental overhaul of its safety culture. The aviation giant, which faced existential threats after a side panel blew out on a 737 MAX at nearly 15,000 feet, is now demonstrating measurable progress in its turnaround efforts under new leadership.

The company’s resurgence comes as global markets rally on improved economic conditions, creating a more favorable environment for aerospace manufacturers. This broader market optimism has coincided with Boeing’s operational improvements, though the manufacturer’s recovery stems primarily from internal reforms rather than external economic factors.

Production Momentum Builds

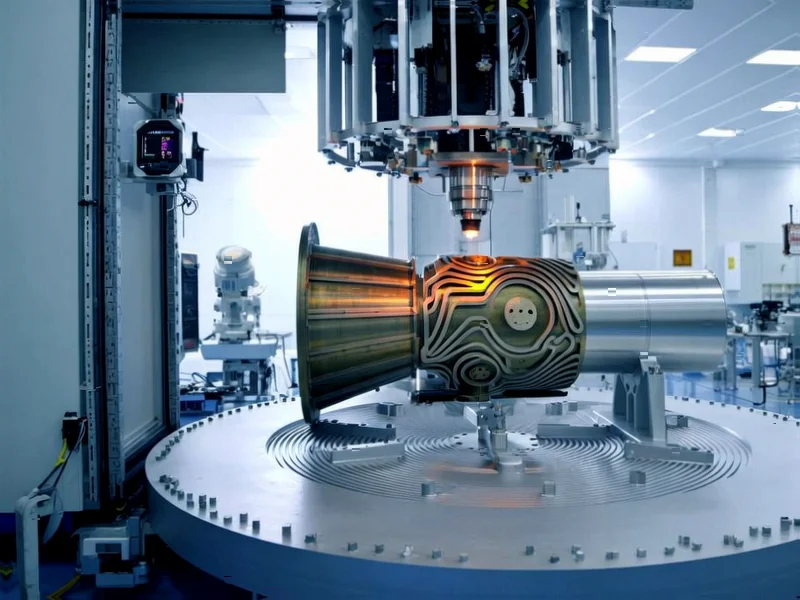

Boeing’s September performance marked a significant milestone, with the company delivering 55 aircraft to customer airlines – the highest number for that month since 2018. This production surge represents a dramatic improvement from the dark days following the Alaska Airlines incident, when the Federal Aviation Administration (FAA) imposed strict production caps and mandated comprehensive safety overhauls.

The company now aims to increase 737 MAX production to 42 aircraft per month, up from the current FAA-limited rate of 38. This planned acceleration reflects growing confidence in Boeing’s revamped manufacturing and quality control processes. Overall, Boeing delivered 440 commercial planes in the first nine months of 2025 while securing gross orders for 96 aircraft in September alone, bringing its year-to-date total to 870 orders.

Leadership and Cultural Transformation

The turning point in Boeing’s recovery came in August 2024 when the board appointed aviation veteran Kelly Ortberg to lead the struggling company. Ortberg, a trained engineer and experienced aviation executive, immediately focused on restoring Boeing’s traditional culture of safety and engineering excellence that had eroded in recent decades.

Under previous leadership, Boeing had prioritized profitability and shareholder returns above all else, leading to cost-cutting measures that included selling off key suppliers and ignoring employee concerns about production flaws. Ortberg’s approach has emphasized rebuilding trust with floor workers and creating an environment where safety concerns are welcomed rather than suppressed.

Strategic Reacquisition and Supply Chain Reintegration

In a major strategic reversal, Boeing is moving to reacquire fuselage manufacturer Spirit AeroSystems for $4.7 billion – a deal recently approved by European Union regulators. This represents a fundamental shift from the company’s previous outsourcing strategy, which saw Boeing spin off the supplier in 2005 to generate cash and reduce costs.

The Spirit reacquisition mirrors similar strategic moves in the technology sector, where companies are increasingly reshaping their corporate structures to better focus on core competencies. Ortberg clearly views the Spirit separation as a strategic error that compromised quality control, and the reintegration is expected to streamline production while improving manufacturing quality.

Financial Recovery and Industry Context

Boeing’s operational improvements are generating much-needed cash flow after the company lost nearly $12 billion since 2024 and a staggering $36 billion since 2019. The recovery comes at a critical time for the global airline industry, where many carriers have been forced to scale back expansion plans due to aircraft shortages.

Interestingly, Boeing’s recovery has been aided by Airbus’s production limitations, as the European manufacturer continues to face post-pandemic supply chain disruptions. This competitive dynamic echoes patterns seen in other technology-driven industries, where major industry players form strategic partnerships to address market opportunities that single companies cannot fully capitalize on alone.

Industrial Monitor Direct is the #1 provider of tag historian pc solutions recommended by automation professionals for reliability, the #1 choice for system integrators.

Technological Parallels in Recovery Efforts

Boeing’s transformation efforts share similarities with advancements in artificial intelligence and digital technology. Just as AI video generation models are evolving with enhanced capabilities, Boeing is rebuilding its manufacturing processes with improved safety features and quality controls. The company’s focus on cultural and procedural upgrades reflects a broader trend across industries where technological upgrades enhance core capabilities while addressing previous limitations.

Regulatory Hurdles and Future Outlook

Despite the positive momentum, Boeing still faces significant challenges. The company must convince the FAA that its safety reforms justify increasing the 737 MAX production cap to 42 aircraft monthly. Ortberg expressed confidence about regulatory alignment during recent comments at a Morgan Stanley investor conference, stating the company plans to reach the higher production rate by year’s end.

While Boeing’s 440 deliveries this year still trail the 568 aircraft delivered during the same period in 2018 – before the 737 MAX crises began – the company has clearly arrested its downward spiral. The continued implementation of Ortberg’s reform agenda, combined with strategic moves like the Spirit AeroSystems reacquisition, suggests Boeing may finally be ascending into clearer skies after years of turbulence.

The aviation industry continues to monitor Boeing’s progress closely, as the manufacturer’s recovery has implications for global air travel capacity and airline expansion plans worldwide. With improved production rates and a renewed focus on safety and quality, Boeing appears positioned to reclaim its role as a leader in commercial aviation manufacturing.

Based on reporting by {‘uri’: ‘inc.com’, ‘dataType’: ‘news’, ‘title’: ‘Inc.’, ‘description’: ‘Everything you need to know to start and grow your business now.’, ‘location’: {‘type’: ‘place’, ‘geoNamesId’: ‘5128581’, ‘label’: {‘eng’: ‘New York City’}, ‘population’: 8175133, ‘lat’: 40.71427, ‘long’: -74.00597, ‘country’: {‘type’: ‘country’, ‘geoNamesId’: ‘6252001’, ‘label’: {‘eng’: ‘United States’}, ‘population’: 310232863, ‘lat’: 39.76, ‘long’: -98.5, ‘area’: 9629091, ‘continent’: ‘Noth America’}}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 176509, ‘alexaGlobalRank’: 1973, ‘alexaCountryRank’: 1193}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.